Tantalum Capacitor: All Things You Need to Know

What is Tantalum Capacitor?

Tantalum capacitors are small in size and can achieve large capacitance products, is first developed by the United States Bell Laboratories in 1956, its performance is excellent. Tantalum capacitors come in a variety of shapes and are made into small and chip components suitable for surface mount. Tantalum capacitors are not only used in military communications, aerospace and other fields, but also in industrial control, film and television equipment, communication instruments and other products.

Types & Dimensions of Tantalum Capacitor

Tantalum capacitors come in various sizes to accommodate different applications, balancing capacitance, voltage rating, and physical footprint. The size of a tantalum capacitor generally correlates with its capacitance value and voltage rating, as well as the specific type of tantalum capacitor (e.g., surface-mount vs. through-hole). Here's an overview of the different sizes available:

1. Surface-Mount Tantalum Capacitors

Surface-mount tantalum capacitors (SMD) are designed for compact, high-density circuit boards. They are available in several standardized sizes, typically referred to by their EIA (Electronic Industries Alliance) case codes, which indicate the dimensions of the capacitor.

Case Code A (EIA 3216-18)

3.2 mm × 1.6 mm × 1.6 mm

Capacitance range: Up to around 47 µF

Voltage range: Typically up to 35V

Case Code B (EIA 3528-21)

3.5 mm × 2.8 mm × 2.1 mm

Capacitance range: Up to around 100 µF

Voltage range: Typically up to 35V

Case Code C (EIA 6032-28)

6.0 mm × 3.2 mm × 2.8 mm

Capacitance range: Up to around 220 µF

Voltage range: Typically up to 50V

Case Code D (EIA 7343-31)

7.3 mm × 4.3 mm × 3.1 mm

Capacitance range: Up to around 470 µF

Voltage range: Typically up to 50V

Case Code E (EIA 7343-43)

7.3 mm × 4.3 mm × 4.3 mm

Capacitance range: Up to around 680 µF

Voltage range: Typically up to 50V

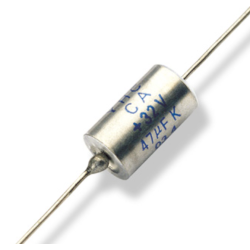

2. Through-Hole Tantalum Capacitors

Through-hole tantalum capacitors are less common in modern electronics but are still used in specific applications where higher capacitance or voltage ratings are needed. These capacitors typically have a cylindrical or radial-lead configuration.

Axial Leaded Capacitors

Size varies significantly based on capacitance and voltage, generally larger than SMD types.

Example sizes: 10 mm × 5 mm (small), 20 mm × 8 mm (large).

Capacitance range: Up to several hundred µF.

Voltage range: Typically up to 100V.

Radial Leaded Capacitors

Smaller footprint compared to axial types, with leads protruding from the bottom.

Capacitance range: Up to several hundred µF.

Voltage range: Typically up to 100V.

Example size: 10 mm height × 5 mm diameter.

3. Specialized Large Tantalum Capacitors

For industrial or high-power applications, tantalum capacitors are also available in larger sizes, often with custom packaging to handle higher voltage and capacitance needs. These are less common but can be used in power supply units, military, and aerospace applications.

4. Subminiature Tantalum Capacitors

Some tantalum capacitors are designed to be extremely small for use in miniaturized electronics like medical implants or ultra-compact devices. These subminiature capacitors are often custom-made, with dimensions significantly smaller than the standard case codes, sometimes as small as 1.0 mm × 0.5 mm.

What Are Tantalum Capacitors Used For?

Tantalum capacitors are widely used across various industries due to their unique properties. In the consumer electronics sector, they are commonly found in smartphones, tablets, and other portable devices. Here are some common applications:

1. In the medical industry, tantalum capacitors are used in life-critical equipment such as pacemakers, defibrillators, and other implantable devices. They are also used in medical imaging equipment and monitoring devices, where stable and precise performance is essential for accurate diagnostics.

2. The aerospace and military sectors also rely heavily on tantalum capacitors. These capacitors are used in radar systems, communication equipment, and various control systems where they must perform reliably under extreme conditions, including high temperatures, vibrations, and radiation.

3. In industrial applications, tantalum capacitors are used in power supplies, automotive electronics, and various control systems. Tantalum capacitors also play a crucial role in renewable energy systems, such as wind turbines and solar power inverters, where their stability and long life help ensure continuous operation.

Advantages of Tantalum Capacitor

l High capacitance in a small size

l Stable performance across temperatures

l Low equivalent series resistance (ESR)

l Low leakage current

l High voltage rating relative to size

l High frequency response

l Consistency in manufacturing

l Good safety margin

Disadvantages of Tantalum Capacitors

l Polarized nature

l High cost

l Limited surge current capability

l Sensitivity to humidity

l Lower capacitance range compared to electrolytic capacitors

What Is the Difference Between a Normal Capacitor and a Tantalum Capacitor?

The primary difference between a tantalum capacitor and a "normal" capacitor, such as ceramic or electrolytic capacitors, lies in their construction, material composition, and performance characteristics. Tantalum capacitors use tantalum pentoxide as the dielectric material, which allows them to achieve high capacitance values in a very small physical size. This is in contrast to ceramic capacitors, which use ceramic materials as the dielectric and are typically larger for the same capacitance value.

Another key difference is in the stability and reliability of tantalum capacitors compared to other types. Tantalum capacitors are known for their stable performance across a wide temperature range and their low ESR, which contributes to more efficient energy transfer and reduced power losses in circuits. This makes them more reliable in applications that require precise and consistent performance, such as in timing circuits or high-frequency filtering.

Unlike ceramic capacitors, which are non-polar and can be connected in any orientation, tantalum capacitors are polar. This means they must be installed with the correct polarity to avoid damage, as reversing the polarity can lead to catastrophic failure of the capacitor. Electrolytic capacitors, another common type, also have polarity, but they typically have a higher ESR and are bulkier compared to tantalum capacitors of equivalent capacitance.

Tantalum capacitors also differ in their longevity and durability. The solid electrolyte in a tantalum capacitor is more stable over time than the liquid electrolyte found in some other capacitors. This stability reduces the risk of the capacitor drying out or leaking, which can occur in electrolytic capacitors, especially under harsh operating conditions. This makes tantalum capacitors a preferred choice in applications requiring long-term reliability and minimal maintenance.

What Is the Alternative to Tantalum Capacitors?

Tantalum capacitors are widely used due to their high capacitance, stability, and small size, but alternatives may be more suitable depending on the specific requirements of a circuit. Here are some common alternatives:

1. Ceramic Capacitors

Ceramic capacitors are a popular alternative to tantalum capacitors, particularly in applications where size, cost, and non-polarity are important. They offer high capacitance values at a lower cost and are available in a wide range of sizes and voltage ratings. Ceramic capacitors are also non-polarized. However, they tend to have higher leakage current and less stability over temperature compared to tantalum capacitors.

2. Aluminum Electrolytic Capacitors

Aluminum electrolytic capacitors are another alternative, particularly for applications requiring high capacitance values. They are more cost-effective than tantalum capacitors and are available in a broader range of capacitance and voltage ratings.

3. Polymer Capacitors

Polymer capacitors, including polymer tantalum and polymer aluminum capacitors, are advanced alternatives that offer lower ESR, higher ripple current handling, and improved stability over traditional electrolytic capacitors. Polymer tantalum capacitors maintain the benefits of tantalum while addressing some of their downsides, such as lower surge current capability.

4. Film Capacitors

Film capacitors are known for their excellent stability, low ESR, and long life. They are often used in power supplies, motor drives, and other high-voltage applications. However, they are generally larger and more expensive than tantalum capacitors, which may limit their use in space-constrained designs.

5. Supercapacitors

For applications requiring very high capacitance values, supercapacitors (also known as ultracapacitors) can be an alternative. They are used in energy storage, backup power, and regenerative braking systems. Supercapacitors offer extremely high capacitance but have lower voltage ratings and are typically much larger than tantalum capacitors.

Can I Replace an Electrolytic Capacitor with a Tantalum Capacitor?

Replacing an electrolytic capacitor with a tantalum capacitor is possible, but it requires careful consideration.

The first consideration is the capacitance and voltage rating. Tantalum capacitors can often replace electrolytic capacitors in circuits where the required capacitance and voltage ratings are within the range of tantalum capacitors. However, since tantalum capacitors typically have lower capacitance values for the same physical size, this substitution might require using multiple tantalum capacitors in parallel to achieve the same capacitance.

In addition, Tantalum capacitors generally have lower ESR than electrolytic capacitors, which can be beneficial in power supply circuits as it reduces power losses and improves efficiency. However, the ripple current rating of tantalum capacitors is usually lower than that of electrolytic capacitors. In circuits with high ripple current, this could lead to overheating or failure of the tantalum capacitor.

How Long Do Tantalum Capacitors Last?

The lifespan of tantalum capacitors can vary based on several factors, including operating conditions, voltage stress, and environmental conditions. Tantalum capacitors are often rated for a lifetime of 1,000 to 10,000 hours at their maximum rated temperature. For instance, many tantalum capacitors are rated for 1,000 hours at 85°C and can last much longer at lower temperatures. When operated at lower temperatures and derated voltages, tantalum capacitors can last significantly longer. For example, a tantalum capacitor might have a typical life of over 10,000 hours at 70°C or 50,000 hours at 50°C, depending on the manufacturer's specifications.

When used within their specified limits, tantalum capacitors provide reliable performance over an extended period, making them a durable choice for long-term applications.

How to read tantalum capacitor?

1. Direct Marking Method

This method involves directly printing the model, specifications, and other relevant information on the capacitor's casing using letters and numbers. For example, a marking like "10μF 16V" indicates that the capacitor has a capacitance of 10 microfarads and a voltage rating of 16 volts.

2. Alphanumeric Code Method

In this method, the capacitance value is represented using a combination of numbers and letters. The letters indicate the unit of capacitance, such as:

l pF (picofarads)

l nF (nanofarads)

l μF (microfarads)

l mF (millifarads)

l F (farads)

This method is similar to how resistors are marked. For instance, 1F equals 1,000,000μF. If the capacitance is less than 10pF, the tolerance is indicated by a letter:

l B: ±0.1pF

l C: ±0.2pF

l D: ±0.5pF

l F: ±1pF

3. Color Code Method

This method is similar to the color coding used for resistors and usually indicates capacitance in picofarads (pF). In some cases, the voltage rating of small electrolytic capacitors is also marked using colors. The color bands near the positive lead indicate the voltage rating as follows:

|

Color |

Voltage Rating |

|

Black |

4V |

|

Brown |

6.3V |

|

Red |

10V |

|

Orange |

16V |

|

Yellow |

25V |

|

Green |

32V |

|

Blue |

40V |

|

Violet |

50V |

|

Gray |

63V |

4. Marking on Imported Capacitors

Imported capacitors often use a six-part code:

1. Type: Represented by a letter indicating the capacitor type.

2. Physical and Structural Features: Two digits indicate the shape, structure, packaging, and lead configuration.

3. Temperature Coefficient: Shown by a letter or color. For example, an "A" in gold indicates a +100 ppm/°C coefficient.

4. Voltage Rating: A combination of digits and letters indicating the effective value and multiplier (e.g., 477 might represent 47 followed by 7 zeros).

5. Capacitance Value: Represented by three digits, where the first two digits are significant figures and the third digit is a multiplier (e.g., 101 means 100 pF).

6. Tolerance: Indicated by a single letter, similar to domestic capacitors.

Some imported capacitors use color codes, similar to domestic capacitors, to indicate values and tolerances.

For example, in a marking like "477 A71N13," the last six digits correspond to the aforementioned six categories.

FAQs

1. What makes tantalum capacitors reliable?

Tantalum capacitors are reliable due to their solid electrolyte, which ensures stable performance and reduces the risk of failure over time.

2. Can tantalum capacitors be used in high-frequency circuits?

Yes, they can be used in high-frequency circuits, but their lower capacitance values compared to some alternatives may limit their application.

3. Are tantalum capacitors environmentally friendly?

Tantalum capacitors are generally considered environmentally friendly, but the mining of tantalum can have environmental impacts.

4. What happens if a tantalum capacitor is installed incorrectly?

Installing a tantalum capacitor with the wrong polarity can cause it to fail, potentially leading to circuit damage.

5. How do tantalum capacitors compare to polymer capacitors?

Polymer capacitors offer similar benefits but are more tolerant to high ripple currents, making them a suitable alternative in certain applications.

Statement: All articles (images, texts, audio) on this site are uploaded and shared by users, or integrated from relevant internet sources, only for user's learning. If your rights are violated, please contact the administrator to delete! Link to this article: https://www.jinftry.com